- Home

- Services

- BOAT TENTS & WRAPPING

- SEACOCKS / HULL REPLACING

- BOW and STERN THRUSTER

- POLISHING

- VARNISHING

- ANTIFOULING

- SANDBLASTING

- OSMOSIS TREATMENT

- SPRAY PAINTING

- REFITS & REFURBISHMENTS

- PLUMBING FITTING SERVICE

- HULL INSPECTION

- GRP REPAIRS

- TEAK REPAIRS

- ELECTRONICS

- MARINE SERVICES

- LIFE RAFT SERVICES

- . . . Why Us

- *** Terms & Conditions ***

- Distributors of

- Chandlery

- REVIEWS

- Contact

OSMOSIS TREATMENT

Osmosis Treatment is a huge part of Slick Hulls work as we are renown for it in the Algarve, we are carrying out this treatment on boats throughout the year, in our large boat shed, within the Marina complex. The problem of osmosis appears in the form of blisters in the gel coat, which is caused by moisture infiltration behind to the gel coat, causing a chemical reaction forming pressure under the gel coat thus creating blisters. The blisters can appear in small or large form in unprotected fibreglass boats. The osmosis problem can occur at any time dependant on a number of factors these range from the quality of the laminate construction, temperature and type of water. Though years of experience Slick Hull has developed a system for the protection to protect against an osmosis problem recurring, this treatment of the osmosis problem has proven extremely successful.

We treat the osmosis by bringing the boats into our workshop, then start the drying process on the hull by using de-humidifiers and infra-red lights. Once a boat is dry we sheave the hull using 300-gram multi bi-axial mat and solvent free resin, before applying a further 5 coats of gel-protect solvent free epoxy, followed by 1 filler coat and then the application of anti-fouling.

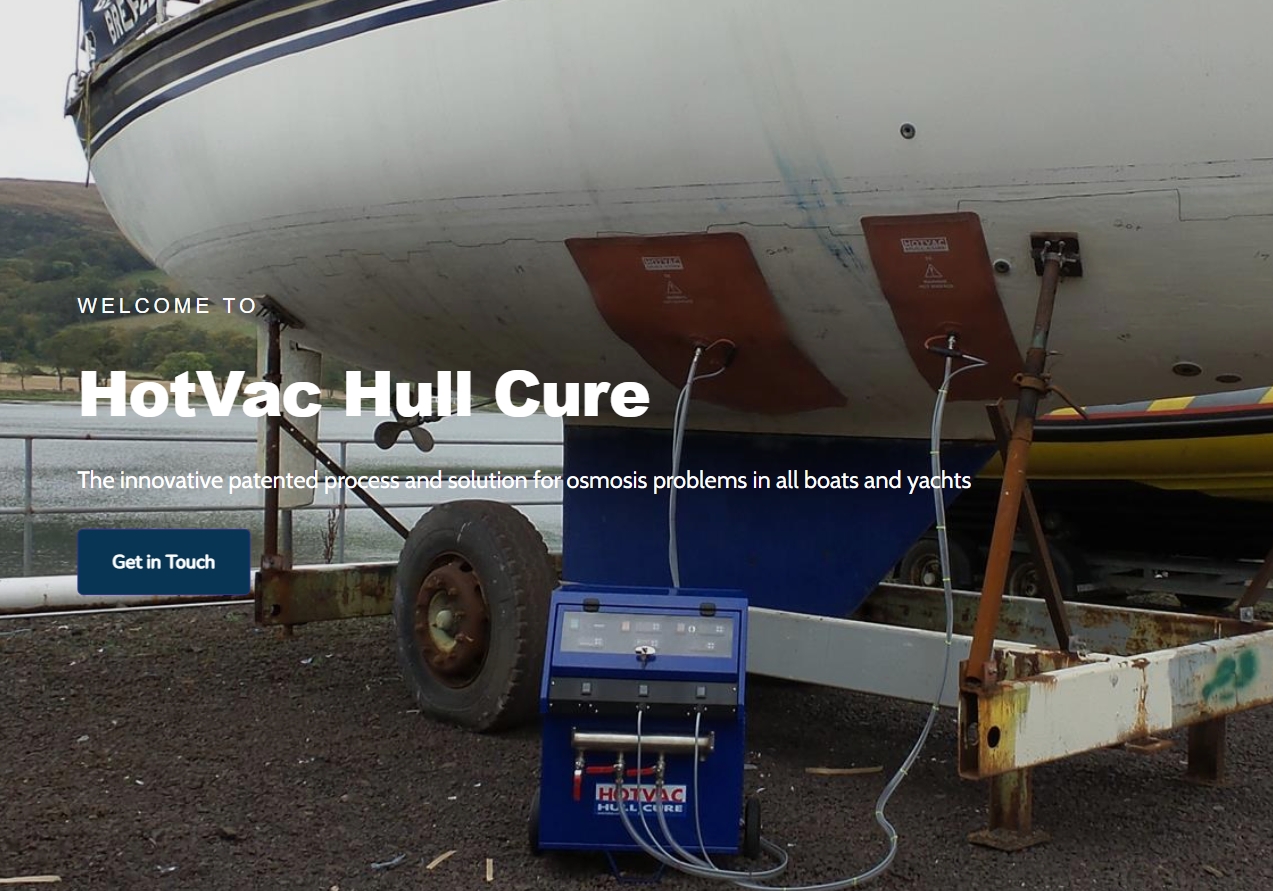

The Solution for Osmosis

A HotVac treatment takes under 10 days for a 10 metre boat - removing the anxiety of waiting to know if the boat will dry - getting you back on the water quickly, and reducing the likelihood of osmosis re-occurrence.

HotVac will diagnose partial de-lamination and confirm severe hydrolysis breakdown. Why use hotvac?:

- Reduce Drying Times to Days

- Post-Cure New Hull Builds or Hull Repair Work

- Remove Osmosis and its Causes

- Restore Structural Strength to the Hull